Image: Rivian

Last Wednesday, after months of building pre-production vehicles, the first customer electric truck drove off the production line at EV startup Rivian’s plant in Normal, Illinois. In doing so, Rivian became the first automaker—beating GM, Ford and Tesla—to build a consumer-ready electric pickup truck.

The milestone also doubles the number of all-electric vehicle manufacturers Americans can choose from, joining Tesla—which has delayed the launch of its Cybertruck, the company’s much-anticipated pickup truck model, until 2022—in the EV-only sector of the market.

“They’re going to be the first to market with an electric pickup truck,” Chris Harto, a policy analyst at Consumer Reports, told E&E News. “That’s a big deal.”

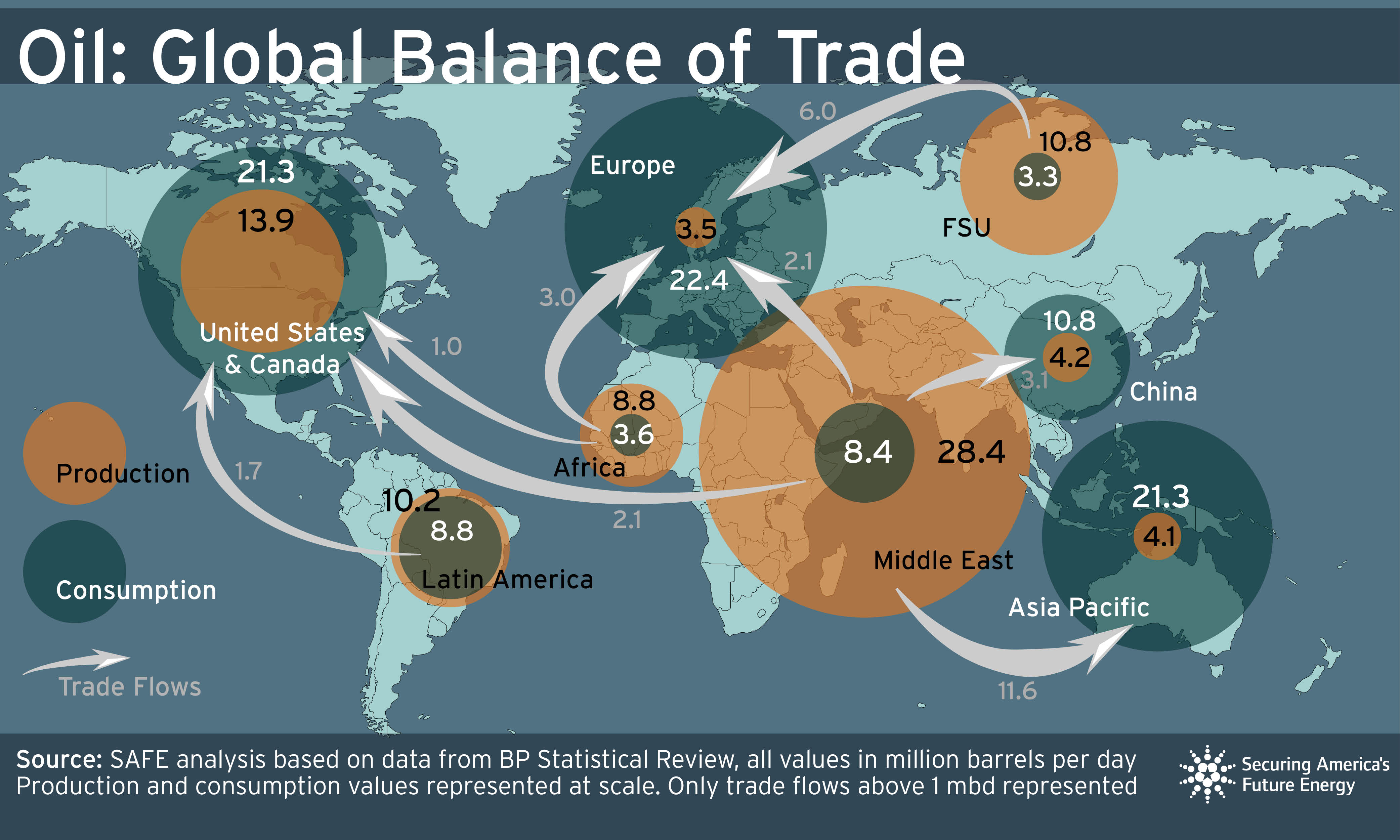

The demographic in question also has significant implications for U.S. energy security: Harto noted that shifting drivers of conventional internal combustion engine trucks to all-electric versions would have a far greater effect on reducing gasoline consumption than moving today’s Prius owners into Chevy Bolts.

However, Rivian’s “electric adventure vehicle” marketing suggests the company has decided to target more recreational truck users, rather than those who drive their trucks for more everyday use. “They’re kind of acknowledging that ‘We’re not marketing to you people who go to Home Depot and throw in a lot of cinder blocks. We are targeting the people who will go into the Michigan Upper Peninsula and rough it for a week,’” said Richard Reina, the product training director at auto website CARiD.

Although Rivian has sold out the launch edition of its trucks, Reina added that truck owners tend to be loyal to the brand of truck they last bought—and noted uncertainty over whether truck owners would be willing to switch over to a relatively unknown brand.

Charge of the Light-Duty Truck Brigade

This question becomes more pertinent as Ford enters pre-production for its F-150 Lightning, the electric version of its bestselling F-series. The company recently announced that with 150,000 pre-orders in hand, it is investing a further $250 million and adding 450 more jobs to boost production at its Rouge EV assembly plant and additional component factories.

Starting at under $40,000, Ford recently announced that it was doubling annual production of the F-150 Lightning from 40,000 to 80,000 per year. “This truck and the Ford-UAW workers who are assembling it in Michigan have a chance to make history and lead the electric vehicle movement in America,” said Bill Ford, the executive chair of Ford.

Yet as automakers old and new compete for leadership in the emerging EV sector, the ultimate winner is the American consumer. A greater variety of EV models are coming onto the market, and advances in battery technologies mean prices are continuing to fall.

However, to truly make the shift toward EVs work in the YU.S. national interest, leveraging this growing market is only the start. We have a window in which to ensure the supply chains that feed this EV shift are built beyond the influence of China, the United States’ near-peer competitor. If it fails to do so, the country risks becoming dependent on Chinese domestic policy for the minerals, batteries and potentially even the vehicles that will power our economy in the 21st century.

To avoid that scenario, the United States should leverage the emerging popularity of new EV models, such as Rivian’s R1T or Ford’s F-150 Lightning, as well as EVs of all vehicle classes from light- to heavy-duty, through purchasing and manufacturing incentives like rebates and tax credits. Electrifying vehicle fleets—including the next generation USPS delivery vehicles—will, in turn, spur investment up the entire domestic supply chain, including battery manufacturing and mineral resource development.

While shifts in policy will be required to create a long-lasting, bipartisan commitment to EV leadership, the foundations for this success lie in creating EVs that consumers want. Electrifying the wildly popular light truck segment is a strong step in that direction.