The power outages that are plaguing China are not just impacting the country’s manufacturing sector—which contracted in September for the first time in 18 months—but are also starting to affect global supply chains as the ripple effects gather pace.

To cope with the power shortfalls, the Chinese government is rationing electricity by ordering factories to work shorter hours and fewer days. As a result, production capacity at some facilities has been cut by one-third.

“What’s happening now is negotiations on how to deal with it – cutting production back during certain peak times, shifting to different shifts or alternating workdays,” said Ker Gibbs, president of the American Chamber of Commerce (AmCham) in Shanghai. “It’s kind of like getting back to the bad old days when there was really a systemic lack of [power generation] capacity before 2010.”

American supply chains—both for companies operating within China and for those dependent on Chinese products—are also being hit hard. U.S. companies operating on mainland China that have contended with the outages have lost business opportunities, cancellation of orders and wastage of raw materials, Gibbs added.

“They were being told literally an hour or two ahead of time that they need to shut down.”

“They were being told literally an hour or two ahead of time that they need to shut down,” he told the South China Morning Post on Thursday, after speaking with around 40 AmCham members from as far as Tianjin in the north to Guangdong in the south. “That type of abrupt shutdown can actually cause damage to equipment [and] even cause safety issues.”

“Companies rely on policy stability and predictability,” added Matt Margulies, vice president for China operations at the U.S.-China Business Council, in an interview with CNBC. “They also need to be consulted with to find nuanced solutions that meet the needs of all stakeholders. A one-size-fits-all approach will be disruptive, increase costs, and hurts confidence in the market.”

The power outages are also expected to further hit semiconductor production at a time when demand, particularly from automakers, is still climbing. In the city of Kunshan in China’s eastern Jiangsu province near Shanghai, one of the hardest-hit areas, more than 10 Taiwan-based semiconductor-related companies filed announcements with the Taiwan Stock Exchange this week saying they are temporarily closing local facilities until the end of September.

“The power cuts could further siphon off buying interest in electricity-powered vehicles.”

Beyond manufacturing, local EV adoption is also likely to be hurt by the outages. “In northeast China, electric cars have been greeted with a lukewarm response for many years,” said Zhang Fan, a car insurance broker. “The power cuts could further siphon off buying interest in electricity-powered vehicles.”

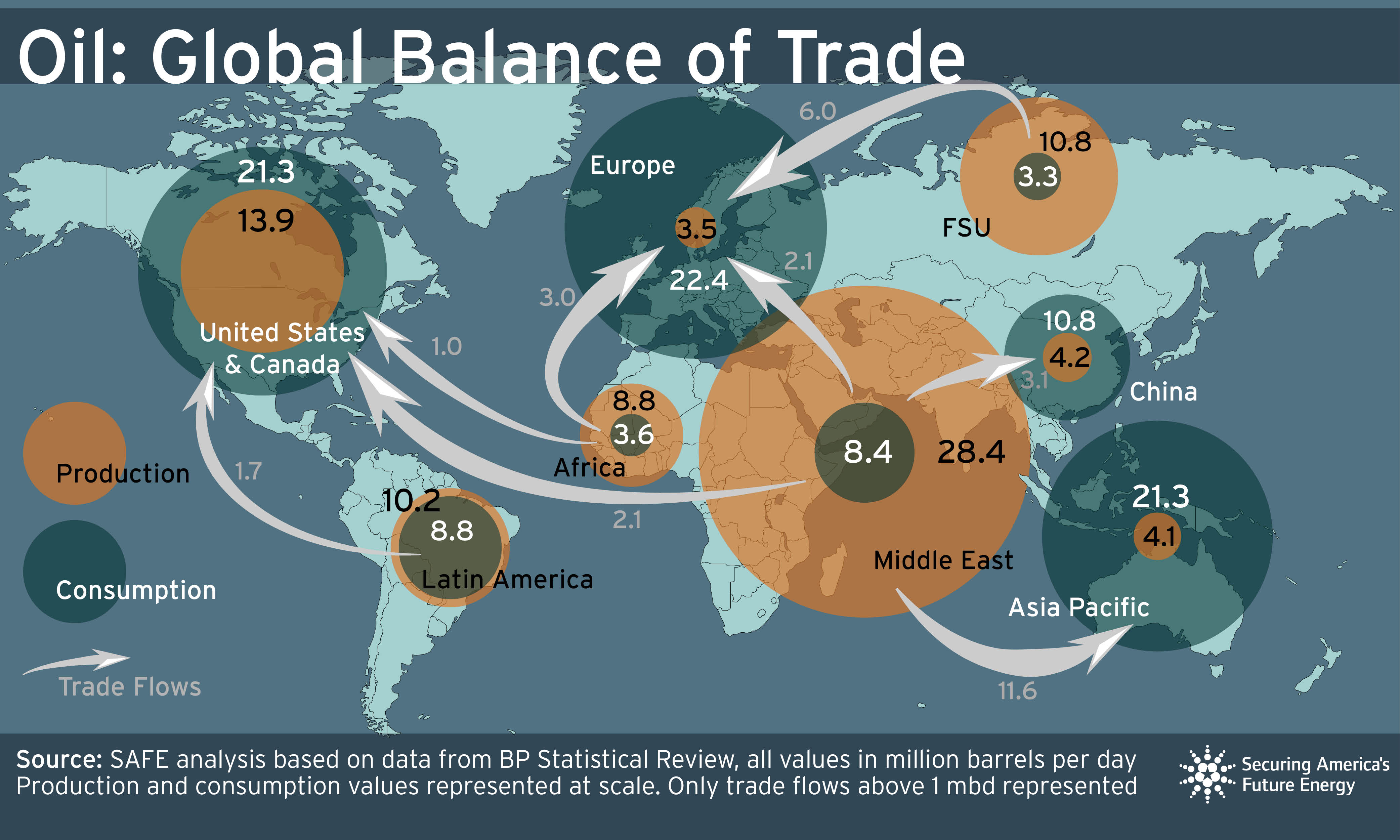

By the end of June, China had more than 6 million electric vehicles on its roads. They need electricity equivalent to about 3 per cent of the total consumption by mainland households.

Yet while some companies continue to deal with the fallout of China’s power outages, others are deciding to invest elsewhere. Johan Annell, partner at consultancy Asia Perspective, told CNBC: “Some companies were on the fence about investing in China. They choose to not go ahead now.”